Industrial giant, Siemens has announced that its latest version of NX software, an industry-leading mechanical CAD and PLM technology, has been updated with Artificial Intelligence (AI) and Machine Learning (ML) for the benefits of its users, increasing efficacy and productivity.

AI and ML and the new NX

Siemens’ use of AI and ML focuses on a new user interface (UI) that can predict what the user is likely going to do next and automatically adapt the user interface to meet the needs of the user. This means different types of users, having different types of needs, can utilize an interface that is responding intelligently to their needs.

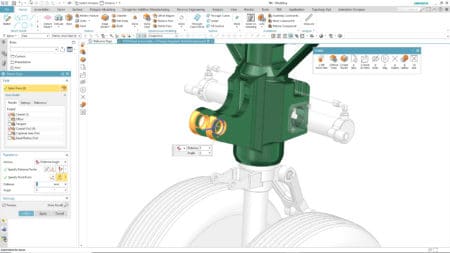

01 – Siemens’ latest NX features AI and ML-driven Adaptive User Interface for optimizing efficacy for multiple user types of CAD users within an organization.

The ability to have an “adaptive UI” meeting the needs of different users across multiple departments can result in higher adoption rates, leading to a higher-quality computer-aided technology system and the creation of a more robust digital twin.

“NX continues to innovate. NX is the first CAD product to deliver capabilities based on artificial intelligence and machine learning,” says HyunMin Kim, principal engineer, Samsung Electronics Co., LTD, “I see value in the new NX Adaptive User Interface for our casual user, to help them with discoverability and improved productivity.”

The Importance of Machine Learning in CAD and CAE

Machine learning (ML) is a subset of artificial intelligence (AI). The algorithms behind AI can be seen as an agent and one definition of an AI is an agent that perceives its environment and takes actions that maximize its chances of successfully achieving its goals. Machine learning has the power to process, analyze, and learn from large volumes of data and can deliver valuable insights about both data and processes.

In this particular case, AI and ML are being utilized so they can monitor the actions of the user, and their successes and failures, to dynamically determine how to serve up the right NX commands and or modify the interface and leverage learned UI usage knowledge for CAx environment personalization.

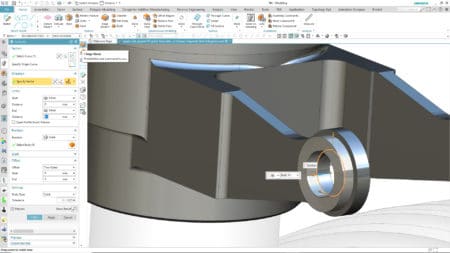

02 – the new NX creates adaptively different user interfaces based on expected tasks to increase user adoption, on-boarding success, and productivity.

“There’s always been a capacity-usability tradeoff with CAD applications. The more expensive it gets, the more difficult it is to use and master,” says Chad Jackson, Chief Analyst at Lifecycle Insights. “The Adaptive UI in NX, however, circumvents that issue. It guides users, new and old, to the right functionality at the right time. Many will benefit.”

AI and ML and the Digital Twin

The Siemens Digital Innovation Platform is continually expanding to enable customers to create the most comprehensive digital twin of the product, the production environment and of the performance of the product. Integrating ML and AI into NX software offers the benefits of speed, power, efficiency, and intelligence through learning, without having to explicitly program these characteristics. This offers many opportunities for customers to enhance design process improvement and ultimately their product offerings and reduced time to market. The NX Command Prediction module is the first introduction of the machine learning-enabled NX adaptive user interface architecture to the market, and will be the basis for, and lead to, additional machine learning-driven UI solutions.

The Limits to Humans of a Static User Interface

“Although extensive research conducted in the field of human-computer interaction has resulted in an excellent static interface, we still lack the perfectly-tailored dynamic interface that can suit all users,” says Bob Haubrock, Senior Vice President, Product Engineering Software at Siemens PLM Software. “The latest version of NX uses machine learning and artificial intelligence to monitor the actions of the user, and their successes and failures, so now we can dynamically determine how to serve the right NX commands or modify the interface to make the individual user more productive. Leveraging this learned-user interface knowledge for CAx environment personalization can help our customers improve overall usage and adoption rates, ultimately leading to a more efficient product development processes.”

To learn more about NX software visit here.

Architosh Analysis and Commentary

Siemens’ new Adaptive User Interface seems to be the first such technology to market. It is not the first time Architosh has seen such technology. We witnessed something remarkably similar under development by the Vectorworks Inc. folks at their annual Design Summit conference last November. It should also be stated that ML has already been released in Bricsys’ BricsCAD BIM which uses AI and ML to figure out on its own what types of objects certain geometry is in a BIM model (ie: is this a door or a wall?) and automatically classify them.

If AI and Machine Learning (ML) within CAD domains interest you please do sign-up for our new INSIDER Xpresso newsletter (which is free) because you will learn a ton about AI and ML in particular and how they are going to change the world of AEC/BIM and MCAD domains.

One thing not stated by Siemens or any of the reporting on this announcement is the typology of the ML used. Machine learning (ML) is tapped for analyzing large volumes of data that the applications themselves capture and send back to the software maker. The ML algorithms in use today essentially learn from data without being explicitly programmed to take a predefined “decision-tree” type of programmed action. There are different types of ML, commonly they are: (1) supervised learning, (2) unsupervised learning, and (3) Reinforcement learning. We will be talking more about which types are commonly used in tools like NX on March 3 when we release issue #1 of Xpresso.

Reader Comments

Also, Graphisoft’s use of multiple processor cores for supportive design-related tasks in ArchiCAD was in use quite a few versions ago.

Also, Graphisoft’s use of multiple processor cores for supportive design-related tasks in ArchiCAD was in use quite a few versions ago.

Comments are closed.