ALTAIR’S TECHNOLOGY FOR AEC GOES back a pretty long way, and in the first decade of this century, we got to know the company through its acquisition of Italy’s solidThinking, Inc. We were already familiar with the Italian software company because, at the time, it was one of just a few CAID (computer-aided industrial design) software systems for both Mac OS X and Windows.

Altair was already a global leader in CAE (computer-aided engineering) software, but as Bob Little, who became solidThinking’s president after the acquisition, said in 2008, “we studied the market and saw that design studios were a special type of place in the product development world.” Noting that C-level executives often had dedicated parking spots outside design studios, the sheer amount of time they could spend there was already well-noted in Apple’s CEO Steve Jobs.

I think with the current speed of innovation and client demands—with the desire to create the most iconic structures with the most energy-efficiency—the dichotomy between the creative and the mathematical cannot be maintained anymore.

The more significant point was, Altair made a vital connection long ago of how critical it was to tie the conceptual design segment of product development to the engineering side. Hence, the acquisition of solidThinking and the continued focus on bringing high-fidelity engineering technology workflows into the early design process.

“I think with the current speed of innovation and client demands—with the desire to create the most iconic structures with the most energy-efficiency—the dichotomy between the creative and the mathematical cannot be maintained anymore,” says Luca Frattari, Ph.D., Vice President, AEC Global Business, Altair. So it goes then that a central tenet of Altair’s overall philosophy has been to find ways to bring high-fidelity mathematically intensive engineering analysis upfront to the design phase.

“We are focused on providing engineers with the tools that make their lives easier, faster, empowering them with optimization tools… On the other hand, we also talk to the architects about the other side, about the simulation tools we have, so they can investigate a freeform design—which is always very hard to understand where the loads come down,” says Frattari. “If you are an architect doing a shape like that, you are unsure where the loads go.”

Pre-Greta Thunberg

After Altair acquired solidThinking and its tools, the company launched a landmark release in solidThinking Inspire 8.0 in 2009, which incorporated its new ‘morphogenesis’ technology, which shipped as an additional module to the base product. It was early Altair optimization technology, and our hero image for our feature article focused on stadium design, a subject of Frattari’s Ph.D. dissertation.

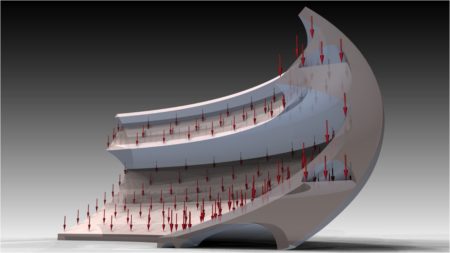

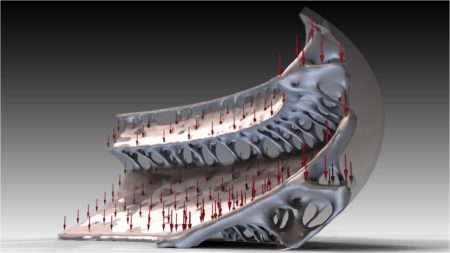

Dr. Frattari’s Ph.D. work focused on stadia design. In this image, loads are applied to a schematic design section. In the next image below you will see morphogenesis technology at work. (click on images for larger views) (Image: Altair Technologies / Architosh. All rights reserved.)

At Architosh, we quickly noted that Altair’s morphogenesis technology could help design efficient and lightweight structures. “Light-weighting designs,” as we sometimes termed it, could save companies millions on transport or fuel or both, including buildings. Altair’s folks noted the positive environmental impacts to industries like aerospace, architecture, ground vehicles, and medical implants back when Greta Thunberg was just six years old.

The same stadia section is now altered through Altair’s topology optimization technology, arriving at “critical mass” reduction, efficient load pathfinding, and shape finding. (Image: Altair Technologies / Architosh. All rights reserved.)

In many ways, from our perspective, Altair was a decade ahead of rivals in the AEC CAD world, who now talk about tools that do what the morphogenesis technology was doing a long time ago. Altair’s engineers took algorithms that scientists created that simulated nature’s reaction to environmental forces—such as those that shaped bone growth in humans and animals. And they applied them to man-made objects. The term morphogenesis has over the years given away to a more general industry term in ‘topology optimization,’ but the goal is the same: create structures with minimum mass and maximum stiffness.

Lighter structures with smaller mass generally are more energy-efficient and more carbon-friendly. Less-weight, less material means less fuel in transport and production.

Inspire and Architecture: A Brief History

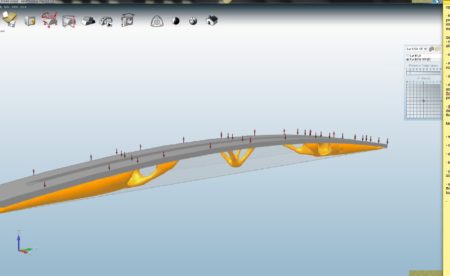

When solidThinking Inspire 8.5 came out in 2011 in the spring, the company had advanced its topology optimization (still called morphogenesis back then) so that individual parts of a model could receive topological optimization or not. Architosh covered this feature in detail around a bridge and chair design. (see image below) By the time version 9.5 came out in 2013, we had noted that its CAID-oriented modeling powers could target that segment of the architecture modeling market seeking more freeform design where there was increasing demand and a small field of capable providers.

Inspire 8.5. had key advancements in isolating topological optimization in specific areas of a model assembly, as shown here in this bridge design where the focus is on the supports under the roadway model.

However, that Rhino-kind of modeling space wasn’t where the company seemed to be oriented. Instead, Altair was at AIA Denver in 2013, where Frattari was talking up their work targeting the SOM’s of the world—and literally SOM of Chicago. The fabled global architecture giant used Altair’s finite element analysis (FEA) software in the early stages of design to provide rapid feedback on very tall structures. This application of FEA in AEC today remains a powerful vector for Altair’s growth with architects and structural engineers. (more on that later).

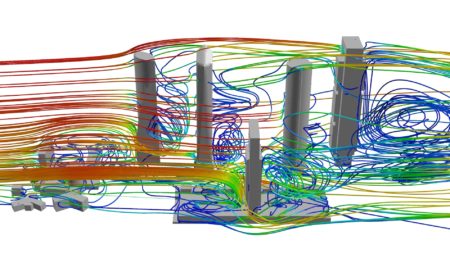

SOM has been a long client of Altair’s technologies, including FEA analysis tools today commonly used for studying wind forces on tall buildings. (Altair Technologies / Architosh. All rights reserved.)

While Altair continued to find traction with large firms like SOM, Architosh itself looked at solidThinking Evolve (not Inspire) in 2013 to exploit its capacity as an advanced modeler with a powerful history tree. Moreover, it ran on Mac and Windows equally, whereas the only CAID-oriented tool directed successfully at the AEC market was the Windows-oriented Rhino 3D. Our modeling feature showcased Gehry-like building surfaces beautifully rendered in metallic-like surfaces. While the article closed with an image of the Gherkin in London by Foster + Partners, Altair didn’t push in this direction, a direction that could have seen it threaten McNeel’s Rhino in AEC.

Instead, Altair, from the mid-decade on and from our eyes, continued to focus on bringing FEA, CFD, and topology optimization to high-fidelity engineering challenges by big-name and marquee architects.

Today Altair has been doing stunning work with firms like SOM and Zaha Hadid Architects (ZHA) which provides Altair key feedback on the evolution of their software technologies for early-stage design development. (more after the jump)

Reader Comments

Comments for this story are closed