(emTech) Section Plus

This feature provides a deeper version of content on emerging technologies, with more analysis on curated news and more product news by (emTech) companies. It is exclusive to annual subscribers of architosh INSIDER Membership.

Special Feature

We published a special feature titled, “The M1 Mac mini vs iMac Pro vs Everyone.”

The Apple M1 chip is an inflection point in the computer industry, marking a third and hopefully final chip transition in Apple’s Mac platform history.

IT WASN’T THAT LONG AGO THAT AMD stole Intel’s single-core performance crown with its Zen 3 chip architecture in the new Ryzen 5000 series CPUs. Now, less than a year later, Apple has come out with a chip (M1) that delivers a stunning performance of its own, and at least by one benchmark is the new reigning single-core performance champion.

But just how powerful is the M1 as compared to rival hardware options out there? And how well might this chip perform in CAD and 3D application environments? These were the questions I sought to answer ever since Architosh obtained a new (late 2020) Mac mini with an M1 processor.

If you look at the performance improvements it is something we haven’t seen in two decades. I strongly believe that this new architecture is a game-changer, especially for pro users.

I already knew Apple Silicon was a possible game-changer. And I had heard stunning praise from CAD industry software developers. But could a sub-1000 dollar machine really be a serviceable CAD/3D machine for professionals? After many benchmarks and real-world app tests (under Rosetta 2.0 no less), the short answer is “yes!”

To read the full story, click here to Xpresso #24 You can subscribe to Xpresso here; it’s free!

The Top Ten Must-Reads

I’ve combed the Internet to find the most interesting, compelling, or controversial stories about the AEC and manufacturing industries, and the social and emerging technological forces at play on both:

1 – Renewed Efforts for a Universal BIM Standard Is a story over at Architect magazine that discusses the technical and non-technical challenges that must be overcome to reach a true OpenBIM standard in the US. (Architect Magazine)

What’s essential in this story? AIA data says that BIM software has increased significantly since 2005, with all respondents in over 50-sized firms saying they use BIM software in some capacity. However, with the increased adoption comes more pressures for universal standards, benchmarks, and file format interoperability in any BIM compatible software. This is a good read that covers all the bases.

2 – Op-ed: Tackling Biden’s climate challenge with artificial (and human) intelligence. Yale’s Phil Bernstein and others take on what it would take and mean to hit US President Joe Biden’s call for “zero net energy buildings at zero net cost.” (Architects Newspaper)

Some highlights Designing such zero net energy buildings at costs that reflect building conventionally will be a massive challenge, but the authors warn that we shouldn’t forget about making positive contributions to architecture and care deeply about the impact of architecture on neighborhoods and the urban fabric. The authors posit that AI may be the key to meeting this challenge—beautiful zero net energy buildings at zero net cost.

3 – 3D-printed home on Long Island hits the market at USD 300,000. Today the news broke across the Internet on this first 3D-printed home on Long Island’s North Shore that hit the market for USD 300.000. (Architects Newspaper)

First 3D-printed house in America to receive a certificate of occupancy and hit the open real estate market. (Image: SQ4D)

What is essential in this story? Just an hour east of the US’s first post-WWII mass-produced suburb, a new experiment in housing is taking place. A three-bedroom home with two full baths and a spacious open plan hit the market. The concrete house was 3D printed using patent-pending technology from Long Island-based SQ4D and their Autonomous Robotic Construction System (ARCS). The house is the first of its kind in the US to obtain a certificate of occupancy.

In other related news, L&T Construction made India’s first 3D printed two-story building. And this story here discusses why 3D printing in construction is one of the fastest-growing segments in the construction industry.

4 – Boston Dynamics introduces new Spot Robot products. The robot dog is clearly a hit and recently we shared that it was now living with Foster & Partners working in the field as a good little robot. (Equipment Journal)

What is new? Boston Dynamics is now offering Spot Enterprise, Scout, and Spot Arm. These new products add value and abilities to the robot dog. Spot Enterprise is a new version of Spot with greater capabilities. Scout is a web-based software that enables control of a fleet of Spots. Spot Arm enables users to act on data insights.

5 – Xerox Takes on Supply Chain Complexity and Fragility with Metal 3D Printing. This manufacturing story at Forbes discusses how Xerox has entered the 3D additive manufacturing industry with new 3D metal printers, addressing both complex changes afoot in manufacturing, including new supply chain pressures brought about by the global pandemic. (Forbes)

Big Picture? Xerox is following HP’s lead in 3D printing. Here we have two conventional 2D printing giants entering the 3D printing industry very late but acquiring smaller companies already in the space.

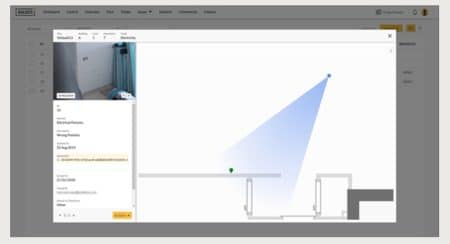

6 – What is a Construction Control Room and Why Do You Need One? This blog post from Buildots talks about looking at the construction control and monitoring process similar to a mission control room at NASA. (Buildots)

Relevancy? — The construction industry has been plagued with zero to slight productivity gains since the onset of the ICT (information communications technologies) revolution, compared to the gains made in almost all other industries. The low rate of “digitization” is largely to blame. Simply put, while the rest of the world’s industries have learned how to benefit from the innovations of the ICT revolution, construction has lagged in its understanding of how to tap digital tools for improving its economic outcomes.

Economists characterize each successive industrial revolution (or techno-economic paradigm) shift as being driven by a primary invention. The invention’s influence extends from its dramatically wide ability to impact and benefit nearly every industrial and even non-industrial activity. Another term attributed to the key invention of an industrial revolution cycle advancement is “key factor” or sometimes called by economists “core input.” Economists Chris Freeman writes that all key factors of each techno-economic paradigm shift fulfill three conditions and we can look at those conditions in relation to construction in a moment. They are:

(1) Clearly perceived low and rapidly falling relative cost.

(2) Apparently, almost unlimited availability of supply over long periods

(3) Clear potential for the use or incorporation of the key factor or factors in many products.

For the ICT era, the key factor is the computer chip (as invented by Intel), measured in industrial economic terms as “operations per cost” (operations per thousand US dollars, for example). A second internal key factor in ICT is the “data transmission size per second” (over the Internet, for example). In the case of the invention of the Internet, the first key factor (microprocessors) is a significant driver of performance advancement of the secondary key factor (Internet speed performance).

It has been noted by economists studying industrial-economic revolutions that small changes on the relative input cost structure have very little effect on the behaviors of engineers, designers, and researchers. Only big and persistent changes have the power to transform the operational common sense procedures within industries. (see: Architosh, “Synergy and Alignment — APIs Democratizing Role,” 3 Oct 2020)

As we stated in the article just referenced, “this means that innovations that seem to speak to new modes of procedural structure in industrial processes but don’t generate rapidly falling relative costs will not yield take-up and re-organization.” Thus, all digitization has meant to the field of construction since the advent of the computer is that it is perceived to have very little chance to generate rapidly falling relative costs. But this is now starting to change as emerging technologies like drones, laser scanners, 3D cameras, AR, and digital design and fabrication (DDaF) process models.

BUILDOT’s solution is 360-degree cameras mounted on hardhats. The video data is converted into a digital twin model that is compared against a BIM model by AI to measure progress and safety issues.

Buildots blog post makes the point that “control room” while commonly associated with NASA actually has its roots in manufacturing. The idea is a room that provides a centralized view of automated processes with continue tracking and measuring of progress. As they state, “one of the main challenges on a construction project includes accessing all of the data from the site and being able to structure it in such a way to get meaningful insights that can be analyzed and actioned accordingly.” Usually, the loss of construction productivity takes place through poor planning when a sub-contractor should arrive but is late and a stage in the work waits for that sub to arrive to do the work, or when a sub-contractor is working at a slower than usual pace and the general contractor is unaware that they are behind schedule.

Buildots solution is aimed at solving that last issue, with hardhat mounted 360-degree cameras. The data is used to create a digital twin 3D model that is compared to a BIM model obviously developed to a high LOD. AI algorithms are then used to automatically generate reports via a comparison between the two models.

One way of looking at this specific technology is to compare it to how it relates to the “key factor(s)” for the current ICT era. Does this process benefit from “operations per cost” in microprocessors? Does this process benefit from advancements in “data transmission size per second”? Or do the three conditions for a key factor actually apply to a new invention, a new “core input”? It is possible the answer is yes, yes, and yes.

For example, forward-looking falling costs in chips means that chips may be embedded in the camera-helmets in the near future. Paired with a smart device, insights might be processed in near real-time while walking around the job site, not just later in a control room. A real-time insight would enable a job super to make an instruction to a sub-contractor on the spot. This happens today without the use of any technology when experienced supers identify issues while walking the construction site. But only if the super can spot the issue. This is where “granularity” comes into play. And that is where AI algorithms can play an outsized role.

7 – The Architect of Modern Algorithms — Barbara Liskov pioneered the modern approach to writing code. She warns that the challenges facing computer science today can’t be overcome with good design alone. (Quanta)

What’s fascinating about this story? — Likely, like me, you have never heard of Liskov, a 2008 Turing Award winner and a member of the team at MIT that created the first programming language that did not rely on “goto” statements. That programming language was CLU, short for “cluster,” and relied on an approach she invented called “data abstraction.” Every modern language today descends from that model of data abstraction.

This article has a lot of interesting takeaways. Liskov says at one point that AI is an application, not a core discipline. But the larger importance of this story is the stunning info on how male-dominated fields like mathematics and computer science actually were (or perhaps are?) back in her time, back in the early ’70s and 80s. Liskov would eventually head the computer science department at MIT, but when she started teaching there the ratio was about 10:1000 in favor of men.

8 – Chipmaking is being redesigned. Effects will be far-reaching. — The chipmaking industry is booming. The capitalization of the world’s listed semiconductor firms now exceeds 4 trillion USD, 4x over what they were worth just five years ago. (Economist)

So what’s the problem, sounds good to me? But in actuality, while chip designs are become more diverse and more specialized, while also general purposes chips are being reduced in size and power requirements to be placed in every “manner of device” in the IoT (Internet of Things) era, at the opposite side of the chip ecosystem are the reduced number of firms that are capable of actually manufacturing ever-increasingly small and specialized chips. In fact, just three firms are able to manufacture advanced chips: Intel, TSMC, and Samsung. The problem is, 80 percent of that manufacturing capability is now in Asia.

And then there are the design side changes. It seems gone are the days when folks got their chips from folks like Intel, IBM, and AMD. Now, software companies are designing chips of their own, including Amazon, Google, Apple, and now soon Microsoft. And then there is a wealth of startups like Cerebras (American)—we talked about them in issue #23 last month—Graphcore (British), and others like Nuvia, which we discuss in our special feature in Xpresso #24. This last company is being acquired by chipmaker Qualcomm.

9 – A new Hub for Danish Robot Developers — 3XN—which is an architecture firm with an advanced research laboratory component called GXN—has designed a new joint home for Universal Robots (UR) and Mobile Industrial Robots (MiR) in Odense, Denmark. (BD+C)

The skinny and importance? The new facility will house most of both organization’s activities, creating the world’s largest hub for cobots (collaborative robots that work and interact with humans).

10 – Exploring the use of artificial intelligence in architecture — This article talks about research at the University of Michigan exploring the use of AI to create new architectural designs. (Tech Xplore)

The interesting and novel. — Matias del Campo and Sandra Manninger, two of the researchers first got involved with AI in architecture prior to 2006, where they worked with Dr. Author Flexer at the Austrian Institute of Artificial Intelligence (OFAI) and held the first course in machine learning for architecture at the University of Applied Arts in Vienna, in 2006.

“Our past papers, including ‘A Question of Style’, ‘Imaginary Maps’ , and ‘Machine Hallucinations’ form the backbone of our recent study,” del Campo said. “The main objective of all these works was to open AI for architecture applications and there are several opportunities to do so. They cover an area that reaches from solutions for optimization problems to novel territories for the interrogation of philosophical questions such as aspects of agency, authorship, and sensibility. In our opinion, this is the very first genuinely 21st-century design technique.”

One dramatic outcome of their research was this. “We realized that there is something the human brain can do that AIs cannot do so well yet: recognize the potential of turning an error into a creative solution.” The two researchers are working on two books on AI in architecture, to be published in 2021 and 2022. “The first book discusses the theoretical implications of using AI to produce architectural designs, touching on aspects such as agency, authorship, and design in a post-human/automated world. The second book, on the other hand, outlines the technical aspects associated with the use of AI in architecture.”

Curated content: Emerging Technologies and their potential impact on CAD-based industries

Apple Entering the VR-AR Headset Market – The New!

A lot of folks have been waiting for this news for a long time. You see, Apple’s Macs have poor VR headset support, and it’s just unacceptable.

Dan Riccio Stepped Down to Focus on AR/VR

Over at Ars Technica, they are covering a story today about Apple’s hardware chief stepping down to take-over full-time leadership on Apple’s long-rumored VR/AR headset.

Last month Apple announced hardware chief Dan Riccio would be stepping down to focus full-time on a special project. But Apple didn’t mention what that product was. Now a report from Silicon Valley publication The Information has revealed what is really going on. (Image: Apple)

Apparently, the VR headset hit a snag under current project leader Mike Rockwell. Rockwell will stay in place but report to Riccio, who will be the top point person in charge. Apple reportedly has over 1,000 engineers focused on this new VR/AR headset device.

A few days ago, The Verge reported that Apple’s rumored VR headset could cost USD 3,000. But if so, the good news is it will feature 8K displays and over a dozen cameras. The Information has a self-created drawing based on “internal Apple images of a late-stage prototype from last year,” and the design features a very lightweight fabric mesh material that helps keep it lightweight on your head, plus design cues from other Apple devices like swappable Apple Watch-style headbands and HomePod-esq mesh fabric.

The device will apparently feature power-hungry 8K displays but not everywhere. Instead, eye-tracking technology will determine where you are looking and set the 8K resolution in just that area and render peripheral areas in lower resolution—a method known as foveated rendering in the VR world. That’s a technique used by Finnish industrial-strength VR/XR-3 headset maker Varjo.

Apple’s VR headset would include some AR functionality, include LiDAR technology like Varjo’s recent advancement (the first to use LiDAR), and be powered by Apple Silicon (a chip as powerful as the M1 is likely). Apple’s patents on its VR headset include names like Avi Bar-Zeev as an inventor. He is the creator of the Microsoft Hololens. He left Apple in 2019.

Further Analysis & Commentary: Apple’s delay in producing a VR headset has never made any sense. Macs’ absence of suitable VR capabilities has been a serious drag on Mac adoption in not just gaming but pro markets like Architecture. While this estimated price is steep, it is similar to Varjo’s professionally-oriented headset, a device that has found a very successful market in the automotive and aerospace simulation industries.

A best-of-breed VR device from Apple that provided unique capabilities on the macOS platform would more than make-up for Apple’s truancy with virtual reality hardware. I guess that this new VR device will arrive simultaneously with the new Apple Silicon-based Mac Pro machines, possibly in Q4-2021.

Tech Soft 3D on Apple, Plus M1

Tech Soft 3D is getting ready for Apple’s macOS transitions, including the deprecation of OpenGL and preferential move to Apple Metal, plus Apple Silicon support.

Tech Soft 3D CTO Gavin Bridgeman said that the company is advancing on both fronts quickly to support developer partners. Moving to support Metal has been relatively smooth thus far, he says. “We already have an abstraction layer in there, so we just need to build and finish our Metal driver, our OpenGL driver, and our DirectX driver, and our tools will look at the system and determine which should be used,” he says.

We do have enough users on the Mac that when Apple switched to Metal, we wanted to lead there. So we are serious about getting Metal done because some of our biggest partners are on Apple iOS and macOS platforms.

Erik Hultgren, product manager at Tech Soft 3D, added, “so even though Windows is our dominant platform—and we are starting to see that for a lot of developers their multiplatform strategy is around using the Web—we do have enough users on the Mac that when Apple switched to Metal we wanted to lead there.” He adds, “so we are serious about getting Metal done because some of our biggest partners are on Apple iOS and macOS platforms.”

Bridgeman and Hultgren said that Tech Soft 3D now has a fully dedicated team working on updating their toolkits for Apple Silicon and Metal. “They are doing nothing but building out that dedicated macOS driver,” adds Hultgren. He says there are actually two teams, one in France and one in America, working on it.”

SolidWorks was the one company anxious to get Tech Soft 3D going on support for Apple Silicon. It wasn’t SolidWorks, however, but eDrawings, the CAD tool that is supported on many different platforms that generated high interest from the MCAD giant.

Familiar with ARM Platform

“We have done work with our toolkits for supporting ARM on the Hololens, so we have done work on ARM already,” says Hultgren. The Microsoft Hololens 2 is run by an ARM processor. Previously it was an X86 processor but today runs on an ARM-based Qualcomm Snapdragon 850 chip based on the ARM cortex technology.

The beauty of Tech Soft 3D and their toolkits is they isolate their partners from feeling the brunt of these OS changes. “They don’t have to change a line of code,” says Hultgren. “We give them the libraries, and they are up and running!”

The M1 support is in beta now out at partners, but the official release will likely be timed with their mid-summer product update.

BIM News

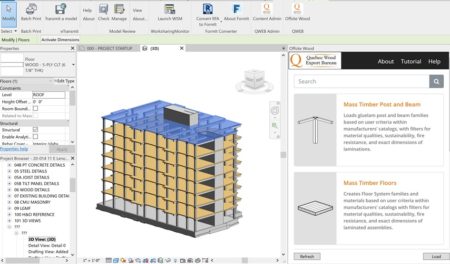

ArchDaily has a good story about the Quebec Wood Export Bureau and their new free BIM plugin on Revit.

The app is called Offsite Wood and helps architects select product families that have the right dimensions, fire resistance, and sustainability profile to meet their needs.

What’s Cooking: Future Xpresso Features

We have recently spoken to The Wild founder and CEO, Gabe Paez about his company’s latest features and how the global pandemic has impacted AEC creatives and driven up interest in VR technologies like his company’s innovative The Wild platform.

The Wild has a new feature called Tours. And it came during the pandemic with great aid to AEC pros using The Wild’s VR collaboration platform. (Image: The Wild / Architosh)

The Tours features enable users to craft a story that will focus everyone around a user’s desired framing. But there is so much more going on at The Wild and great perspectives from Paez about the future of this kind of technology. Don’t miss next month’s issue.

We look forward to sharing this story in Xpresso #25 in March.

Closing Notes

Another item on my mind is explaining to you all that the Xpresso Index and Glossary are still on the horizon. It has been moved back to Q1, 2021 to align with other Architosh site development updates.

Reader Comments

Comments for this story are closed