(emTech) Section Plus

We are shifting gears as readers tell us they would prefer more of our emerging technologies (emTech) content, not “earlier access.”

From now on our previously titled “Early Access (emTech) Section for INSIDER Xpresso” reports will be called “Member Access—(emTech) Section Plus.” Each issue will arrive on or around the same day as that month’s Xpresso newsletter. Xpresso 19 came out three days ago, for example.

(emTech) Section Plus is about providing “more” content on emerging technologies—the primary topic of the Xpresso newsletter. This deeper version of (emTech) is provided exclusively for annual subscribers of architosh INSIDER Membership.

Special Feature

We published a special feature in Xpresso 19 titled, Zach Soflin Talks to Architosh About Layer App.

THERE IS A VERY GOOD CHANCE a lot of Xpresso readers have not heard of the Layer App. Born out of the mid-west from within an architecture firm (BVH Architecture) and generated to tackle the needs of an extensive rehabilitation project to Bertram Goodhue’s icon Nebraska State Capitol, Layer as first seen at AIA was a striking example both good “mobile-first” software design but also excellence in integration-oriented design.

In our Curated emTech section below we continue in-depth about the importance of software integration as it relates to BIM (Building Information Modeling), but Layer too is itself born out of this recognition that interoperability—at the granular level of data—is vastly more important than interoperability of file types.

In our discussion with Soflin, who is a licensed architect, we delve into the Layer App and why it is a key new application in AECO.

Layer — What It Does

Layer is an application that addresses the needs of managing the profound amounts of data (information) typical of most building projects. While the Layer App began from the side of “design” in the design-build-operate model, Soflin and his team saw early interest from both “build” and “operate” professionals.

We have aspirations to reach every single BIM platform, including Open BIM file types.

Layer is a completely flexible and customizable project management application that is built for use in the field, the job site trailer, and the office. “A lot of our overall vision for what the platform can provide is aimed at beyond the design professional,” says Soflin. “Layer is a platform for the entire building lifecycle.”

To read the full story, click here to Xpresso 19. You can subscribe to Xpresso here, it’s free!

The Top Ten Must-Reads

I’ve combed the Internet to find the most interesting, compelling, or controversial stories about the AEC and manufacturing industries, and the social and emerging technological forces at play on both:

1 – Artificial Intelligence Can Improve Process Management in Construction, is the title of this Forbes piece by David A. Teich, featuring the mention of Buildots, a company working to use computer vision to compare a construction site to the plans (or more correctly BIM models) of a future building. felt. (Forbes)

What’s new about this? We have seen robots fitted with cameras collecting and streaming video to AI-instilled software to analyze a construction site to a BIM model and data. What’s new here is that the camera is construction helmet-mounted. It takes video at 2-fps. It doesn’t need a smooth video; it uses just lots of images. And like other systems, they are feed to AI-based software to inspect and compare.

2 – Katerra sheds 400 more employees. The fourth round of staff cuts at construction unicorn Katerra leads to 7 percent of its workforce getting pink-slipped. This follows the replacement of founding CEO Michael Marks with Paul Kibsgaard, instituted by SoftBank which has invested USD 1.4 billion in Katerra. (Silicon Valley Bus Journal)

Katerra goes through more staff changes but the SoftBank-based company is North America’s largest mass timber producer and the only company offering end-to-end mass timber design, manufacturing, and construction. (Image: Katerra)

What’s the low-down? SoftBank has invested a ton of money in this construction unicorn and recent changes are driven at accelerating a path to profitability. This report notes that Katerra has 6,000 multifamily units under construction and other recent reports note that the Menlo Park-based company (valued at USD 4 billion) North America’s largest mass timber producer, offering end-to-end mass timber design, manufacturing, and construction. This makes it a pivotal green economy new company in the AECO space.

3 – Computational design helps deliver Australia’s largest sustainable tower. This piece in BIM Today discusses 6-8 Parramatta Square, part of one of the biggest sustainable urban projects in Australia. Designed by Johnson Pilton Walker (JPW), these stunning new towers use Bentley’s GenerativeComponents (GC) technology inside Bentley OpenBuilding Designer BIM software. (BIM Today)

A street-level rendered view of 6 & 8 Parramatta Square, designed by award-winning Australian architecture firm Johnson Pilton Walker (JPW). (Image: JPW / Architosh. All rights reserved.)

What is valuable in this story? The important piece about 6-8 Parramatta is the unique use of computational design to solve problems for the architects and their consultants and the general contractor in the later stages of the project. Usually, we see AAD (algorithms-aided design) technology deployed in the design stage. Architosh recognized the unique aspects of this Bentley Year-in-Infrastructure Award-Winning project last year and wrote an in-depth feature here.

4 – ETH Zurich Researchers Develop Novel DFAM Framework for Multi-Flow Nozzle Designs Unique research work coming out of ETH Zurich has implications for the world of 3D printing or computational design for additive manufacturing (DfAM). The work focuses on a computational design framework for FDM nozzles. (3DPI)

What’s new about this? This research is essentially saying that complex parts require complex tools, in this case, more complex 3D printing nozzles. For those interested in 3D printing or DfAM this is a must-read. The article also links to similar research at other universities, including Harvard.

5 – Parametric design: style and substance? Computational design is not “wacky” form-finding, begins this article by Ben Knight writing for the newsroom at UNSW in Sydney, Australia. Knight is writing about the importance of “parametricism” as championed by principal architect Patrick Schumacher of Zaha Hadid Architects. This article is ultimately an argument for parametricism not as form-finding but solving more critical issues in architecture. (UNSW)

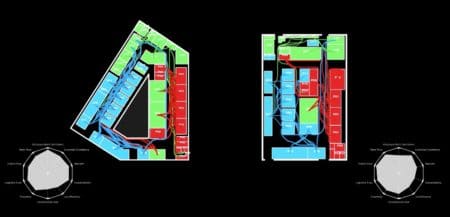

Computational design was used for this project that solved for optimal floor plan configuration to best enable efficiencies. This had little to do with the parametricism used strickly for form-finding and everything to do with building performance against a measurable and understood metric.

A sign of the future? Quoting UNSW associate professor M. Hank Haeusler, “for us, the engagement with computational methods and tools isn’t to change the way the architecture looks, as a new parametric design style.” He says they are teaching computational design methods to solve the grand problems facing architects.

6 – Architecture graduate student recognized with computational design award.

Özgüç Çapunaman, a doctoral candidate in the Stuckeman School’s Department of Architecture, has been recognized for his research by the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA) as the recipient of the Young CAADRIA Award. His research centers on interactive digital fabrication, programmable composites, computational making, and architectural tool development. (Archinect)

One to watch because! Çapunaman’s paper submission focuses on interactive digital fabrication workflow. His research, which he began to establish during his time at Carnegie Mellon University, aims to question the human relationship with digital fabrication tools that are used in the field, such as CAM and CAD.

“The paper presents an interactive and adaptive design-fabrication workflow where the user can actively take turns in the fabrication process,” Çapunaman wrote in his abstract. “The proposed experimental setup utilizes paste extrusion additive manufacturing in tandem with real-time control of an industrial robotic arm. By incorporating a computer-vision based feedback loop, it captures momentary changes in the fabricated artifact introduced by the users to inform the digital representation.”

7 – The Secret of AI is People.

Too many business leaders still believe that AI is just another ‘plug and play’ incremental technological investment. In reality, gaining a competitive advantage through AI requires organizational transformation of the kind exemplified by companies leading in this era: Google, Haier, Apple, Zappos, and Siemens. These companies don’t just have better technology — they have transformed the way they do business so that human resources can be augmented with machine powers. (Harvard Business Review)

Why is this story important? A multistage five-year study looked at five leading organizations and what brought them success with AI. The big take-away is counter-intuitive—it’s not about bein technology-driven or tech-forward. The secret is making the businesses model transformations so that automation augments humans and vice versa. Human skills matter—creativity, care, intuition, adaptability, and innovation are areas machines cannot match humans. To read how leaders get the most out of AI putting humans into the equation for maximum success, read here.

8 – Builder a Better Machine for an AI World. Raja Koduri has been in the thick of the past two eras of computing, which were marked by – among other things – the ability to architect systems and software that helped to get more performance into the hands into increasing numbers of people. From leadership stints at AMD (twice), Apple, and now Intel, he is currently Intel chief architect, vice president, and general manager of the Cores and Visual Computing and Edge Computing Solutions unit at Intel. (The Next Platform)

These human skills cannot be “botsourced,” a term we use to characterize when a business process traditionally carried out by humans is delegated to an automated process like a robot or an algorithm.

Why is this story important? Raja describes how we went from 1 billion PCs in the era of the personal computer and Internet to 10 billion devices in the mobile plus cloud era, and now we are moving toward the 100 connected devices, with IoT and AI and the need for exascale computing. “All of this represents a 10-fold opportunity for the IT industry, but it’s going to demand massive amounts of expensive compute power, a demand that already is doubling every three to four months, Koduri said. By 2025, the world will be creating 175 zettabytes of data.”

9 – Apple Silicon Macs—chip production on schedule. Chip production for the first Apple Silicon Macs is reported to be on schedule for launch before the end of the year. (9to5 Mac)

The new ARM Macs will be based on an Apple chip architected around the specific needs of each Mac device—from mobiles to the Mac Pro.

What Macs will get Apple Silicon First? Apple will be delivering 5nm SoC (system on a chip) processors for its next-gen Macs in the 4th quarter of 2020, according to reports. 5nm is vastly smaller than the 14 and 10nm processors from Intel, and will thus enable Apple significant advantages to pack tremendous compute power inside its svelt form-factors. While there are conflicting reports of a 12-in MacBook versus a new iMac and a new MacBook Pro being first to obtain Apple Silicon, either way this is an important inflection point in the computer industry.

10 – The Dusty Robotics CEO Tessa Lau Discusses Robotics Start-Ups and Autonomous Robots for Construction. Tessa Lau is Founder/CEO at Dusty Robotics, whose mission is to increase construction industry productivity by introducing robotic automation on the jobsite. Dusty’s FieldPrinter autonomous mobile robots prints layout plans directly onto the floors of job sites using information from building information models (BIM) as a guide. (Robotics Business Review)

The importance of Robots in AEC. Having a robot print out the floor plan on the concrete deck of a building is a non-obvious win-win for AEC. It’s a task that gets done with people and transits and tape measures. But Tessa Lau’s robot ingests BIM documents and with that data in-hand can play a significant role in augmenting human tasks on the job site. Read on to learn more about their USD 5 million seed round.

Curated content: Emerging Technologies and their potential impact on CAD-based industries

The Future of BIM Interop:

Recently, after we published our first article on the Revit Open Letter by a group of British architects, I was contacted by the folks at 3D Repo, in the UK. Dr. Jozef Dobos, CEO of 3D Repo initially wrote in to discuss his views on the Revit Open Letter movement. He also, however, shared his views on the future of interoperability (interop) in the AECO industry.

AEC Delta Project

Dr. Dobos chimed in on the Revit Open Letter partly because he felt the AECO industry is at an important inflection point in its digital tools history. Being that better “interoperability” was one of the main sticking points in the open letter he wanted to introduce to Architosh his company’s work on an open-source technology his company helped create and shared and is known in the industry as the AEC Delta project.

A lead slide image from the Dr. Al Fisher presentation on the AEC Delta project. (Image: Buro Happold)

The AEC Delta project, in a nutshell, is an API technology project that enables applications to talk to each other and exchange data, including BIM applications. Some of the technology is embedded inside 3D Repo’s namesake web application focused on the AECO industry.

Dr. Dobos explained that AEC Delta is a collaboration between several companies in the UK that began in 2019. The notable engineering firm Buro Happold is one of those companies. As part of the Innovate UK-funded project, Dr. Al Fisher of Buro Happold goes through what AEC Delta is all about in this recorded event (here on YouTube), noting that AEC Delta, as a funded project, included partners Buro Happold, UCL, Rhomberg Sersa (Rail Group), and 3D Repo. Additional partners include HOK, Georgia Tech, ARUP, Hypar, SNC Lavalin, and Atkins.

The project has three project deliverables, including an Open Delta specification, an open REST API specification, and open-source reference implementations.

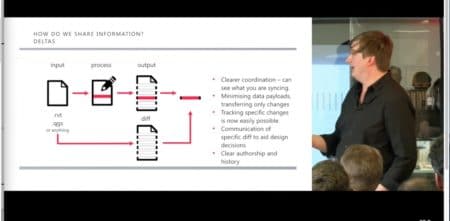

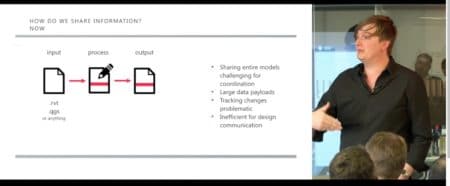

The specific problem being addressed is how we share information in the AEC BIM industry. Today we share entire models (files we pass back and forth) but in the future, we will share only the data that has changed in models (deltas). (see the images above and below.)

Another view showing how “information” would be shared using a modern “diffing” process where software solutions pass along only the changes or “deltas” between systems which would be connected via APIs and talk to each other in often real-time methods.

The current method is just as inefficient as in the world of changing 2D drawing files, to some extend. Both methods create large payloads, create problems for tracking changes, and are inefficient. AEC Delta project technology wants to be “transactional” not on a “file basis” but on a “diff” (diffing) basis. The term “diffing” comes from the GitHub world and it relates to how modern software is developed across geography and time.

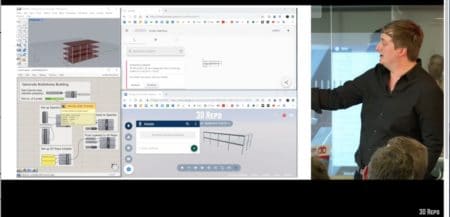

Rhino and Grasshopper are talking to 3D Repo and Speckle Works applications using this new AEC Delta open-source technology using Buro Happold’s HBoM (life adapter) that passes data across the applications shown above. Watch the video here.

Dr. Al Fisher shows in his talk early work at Buro Happold linking in their internal code (a plugin inside Rhino+GH) based on AEC Delta open-source specifications connecting to Speckle Works and 3D Repo. You can see all three applications updating each other using this new open-source AEC Delta technology at 11:13 in the video here. One has to admit this technology is cool and exciting!

You can see Buro Happold’s contribution to this project here at The Buildings and Habitats object model (BHoM) web page.

Further Analysis and Commentary: Here I would like to point out that one factor helping drive the push for software in AEC that is less file-dependent for interoperability (interop) is the general push for applications in the cloud. If you noticed, one of the company’s listed in the Dr. Fisher seminar was Hypar. Hypar is entirely cloud-driven and you operate it in your browser. It can ingest files and output files but the large point is it represents the types of AECO industry tools that represent the future. It is not surprising to see them get involved in the AEC Delta project.

ASITE and 3D Repo

The folks at 3D Repo are very serious about the future of BIM/AEC interop. As one of the partners in the AEC Delta project, they have developed their own Diff technology and APIs to pass data back and forth to other applications. Dr. Jozef Dobos shared with me several webinar recordings that have taken place in the recent past. One of those was a webinar with ASITE and 3D Repo focused on custom integrations using each other’s respective APIs.

As explained in the webinar (which you can watch here, in full) ASITE sees themselves as “primarily in the business of holding data.” And of providing that data to other software systems for use.

ASITE features “workflows” which are fully customizable and can involve third-party applications via API integrations. In this particular webinar, the focus was on the integration between ASITE and 3D Repo. To build automation between these two platforms “trigger” events are built into each application (into specific workflows in ASITE, for example).

ASITE’s Take on Software Evolution

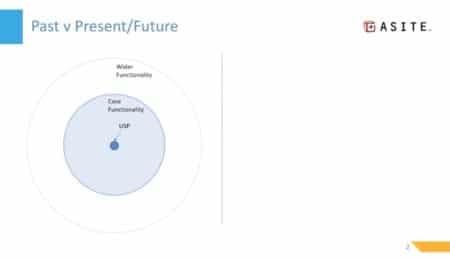

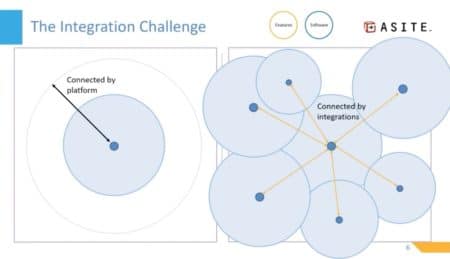

One of the more fascinating moments in this webinar recording was the discussion about the history of software. Traditionally, when new and successful software enters the market it offers a “unique selling point” (USP). Essentially, the entire software product builds features around its USP known as its core functionality (CF). (see the diagram below.)

Rob Clifton, senior VP, ASITE, explains during this talk about how software has existed in the past (left in the diagram above) and how the present and future are shaping up. Successful software begins with a USP (unique selling point). Core functionality wraps the USP, but wider features add functionality that is not intrinsic to the USP and often overlap with competitor products. (wider functionality is outside core functionality and therefore does not deepen the USP.

When software expands its feature set it moves further away from its USP. This has two often undesired consequences. A widening of features places the software application in an ever-widening overlap with competitor software, while also diminishing focus and resources on the USP.

Tech giants try to cover everything. Because they offer “connected platforms” there is an advantage in their tools working together. (think Microsoft, Adobe, and Autodesk, as examples). But this diversity and wide breadth of coverage tend to take away from focusing on their core areas of expertise and their USPs. The giants focus on tie-ins in their suites and platforms selling the virtue of strong connections and interop via “the platform.” (eg: Microsoft leveraging its OS with its own web browser — see the left side of the diagram below).

In the past, the value of software was placed on the strength of the USP. The strength of connections was often based on the software being connected by a platform under one company. But today’s market is shaping up differently. Through API integrations, unique USPs from diverse software solutions can be connected to each other—not by virtue of a single platform under a single company but—via APIs built on solid and open technologies freely available to all.

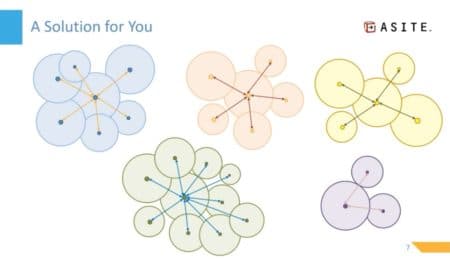

ASITE says the focus today in software is building out technologies that enable great connections between tools that are owned by separate companies and our outside major platforms, offering the advantages of connected data without the disadvantages of “legacy-oriented” file-based interop limitations. This is precisely what Zach Soflin, founder of Layer App, is talking about in the special feature above.

The advantage is you get better coverage of your business’ requirements (being able to use best-of-breed tools together via API connections) but also gain the advantage of setting up your solutions in a much more personalized way than one can do with limiting yourself to collections of tools in single company platforms.

By leveraging a diverse set of USPs (multiple best-in-breed tools) and building out custom workflows via API integrations, companies to tailor digital solutions to their specific needs at ever more personalized and effective levels.

Rob Clifton, senior vice president of ASITE puts it this way: “…it is important when you are selecting software to work with that it is apart of this larger network of integrations. Software that sits out on its own and integrates poorly does not offer you the same potential and capacity going forward and is not as future-proof as those that are really connected to this web of software solutions.” He draws the comparison to Apple’s iPhone and notes the phone is the platform but all the apps on it are customized to each person.

To watch this presentation in full go here.

Further Analysis and Commentary: In watching the ASITE and 3D Repo presentation the ASITE folks did note that to the uninitiated, setting up custom workflows in ASITE takes some training and experience. But it does not take any programming experience. This is a no-code / low-code environment.

In general, the larger point is that building custom workflows are worth it. One example showed the integration of SafetiBase with 3D Repo. “Pins” for the location of safety issues noticed in the field could be automatically located back in 3D Repo in the BIM model view. Likewise, another example showed how to add a barcode reader field to a custom tool built with Microsoft’s Power Automate and Power Apps and have that data passed back to 3D Repo automatically upon scanning an item in the field.

Further 3D Repo Discussions

Dr. Jozef Dobos keyed us into several 3D Repo webinars that are recorded that cover other integrations and just 3D Repo in general.

For example, there is a case study on 3D Repo and SafetiBase, which is an app focused on job site safety management. This is a PAS 1192-6 compliant risk register and database solution. More on this use of 3D Repo and SafetiBase can be found here.

For the Hinkley Point C project in the UK, 3D Repo’s patent-pending 3D Diff change detection tool is discussed in detail. This is another interesting case study of cloud-based AECO tools talking to each other in an intelligent integrated workflow offering great advantages over the limitations of passing BIM files around the AECO world of stakeholders.

Another 3D Repo case study worth looking at is this one on the Canary Wharf Wood Wharf project. And finally, this case study looks at PlanBase and 3D Repo for a planning portal for the Greater London Authority and London’s Mayor’s Office.

Digital Tools for Building Integrations

Tools for helping users build-out “integrations” between software systems are growing and the ASITE and 3D Repo webinar listed several. While ASITE’s webinar touted the virtues of Microsoft’s Power Automate (formerly Flow), competitors include all of the following:

- boomi — their tagline is “instantly connect everything to everything.”

- MuleSoft — this tool offering seems like Zapier for enterprises, in other words, connecting more enterprise software solutions together rather than consumer/prosumer oriented tool offerings.

- Zapier — a mainstay in the integrations game, Zapier is aimed at small to medium enterprises (SME) and we at Architosh already have good experiences with Zapier for several automations used for both Architosh and for AEC projects.

- Node-RED — this is a low-code programming tool.

- Power Automate (Flow) — this is Microsoft’s tool now and was used in the ASITE to 3D Repo integrations seen in the webinar discussed (video here).

One could search the web for even more integration offerings. Some of these solutions have traction in the AEC space due to their early lead in the integrations market. For example, Zapier has integrations with Procore where you can receive a digest email from Procore’s RFIs. You can also set up Zapier to send you an SMS text message when a new RFI is created in Procore. Procore itself has an App Marketplace dedicated to integrations that exist while its published APIs enable folks (both software companies and end-users with software skills) to build new integrations. After all, this is the future folks!

Zapier even let’s site visitors select a professional role (eg: Project Manager—which is appropriate for AECO folks) and it will list out what they call Zap Templates that match a selection of your apps and how Zapier has pre-existing integrations. See this page to start.

As noted above, another aspect noted in the webinar was using 3D Repo as a hub and looking at how to connect to various AEC workflows and it with Microsoft PowerApps. This tool, too, has competitive offerings but it was PowerApps shown in the webinar.

- Retool — connect to most databases and anything with a REST, GraphQL, or gRCP API.

- Betty Blocks — this offering is all about how humans with ideas are the future, not systems. They have a tagline that says, “By 2023, anyone can build an application.”

- JotForm — which was used in the 3D Repo webinar. It’s an easy-to-use online form builder.

- Amazon Honeycode — another Betty Blocks competitor by the Amazon giant! No programming needed to build bespoke apps for your workflows.

- PowerApps — Low-code solution by Microsoft.

The Revit Open Letter

An Update

Over the past few weeks, I have had the opportunity to speak more with lain Godwin, the AEC industry veteran and IT consultant who has helped co-ordinate the Revit Open Letter initiated in Great Britain. I also had the opportunity to interview Autodesk CEO, Andrew Anagnost. Let’s start with the update from Godwin.

The ‘Letters to Autodesk” website went up in August to expedite the ability for firms to sign the letter. From my latest conversation with Godwin, the total signatories are now nearly 200 firms around the globe, in total with a significant number who signed anonymously. I understand from both Godwin and Anagnost that Anagnost and a small Autodesk team held a virtual meeting with the original British group of signatories. Anagnost on my call with him noted it was a productive call but that the contents of that call were confidential amongst the participants. Godwin was not a party to that meeting but did hear sentiment from the British firms who were attendees.

One of the issues that is a sore point with the signatories was apparently the group’s feelings about Anagnost’s defense of Revit software costs. Anagnost personally penned a blog post on Autodesk’s website addressing the British firms and the post had mixed reactions globally. In my call with Anagnost, he spent only a small amount of time addressing the licensing cost issue but I pushed hard to explain from an architect’s experience (in this case my three-plus decades as an architect) that not everyone who works in a CAD or BIM program does so every day or even every week. I suggested that if other software companies can implement “usage-based” licensing (named or otherwise) that Autodesk could also. Anagnost agreed and said that their users’ licensing issues will get addressed more fully in the near future. The named licensing model does not preclude the ability of Autodesk to implement licensing models based on usage.

Issue Index

I have mentioned the following companies and solutions in this issue (see above):

We listed several tools in the section above titled, Digital Tools for Building Integrations.

Closing Notes

We planned to introduce version 1.0 of our Xpresso Reader Glossary and Index but we were unable to hit our deadline. So look forward to this next month for sure!

What did Architosh INSIDER members Get

Member Access—(emTech) Section Plus articles like this one provide architosh INSIDER annual subscribers with more of the content in our (emTech) section of our free monthly newsletter. While this article above features much of the latest issue of Xpresso (#19), all of the Further Analysis and Commentary sections, and all of the Architosh Blue text is bonus material just for this article—just for annual INSIDER member subscribers like you.

In addition, the Top Ten Must Reads actually feature 10 curated stories with our commentary and analysis of why we selected them. In Xpresso, only five our provided.

Member Access articles are a premium bonus to annual subscribers that add to the “unlimited site access” nature of your subscription. Thanks for subscribing!

Reader Comments

Comments for this story are closed