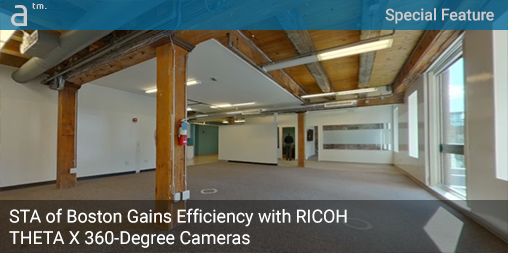

“ONCE A WEEK, WE GO TO the job site,” says architect Bobby Main of Boston-based STA Design (STA), an architecture and interior design firm with expertise in multiple markets with often one thing in common—designing something new in existing spaces. “It’s rare for us to design something from the ground up,” he adds, noting that the first critical step in their projects is obtaining accurate and comprehensive information about an existing space.

Data and Existing Conditions

Nearly all architects and interior designers are familiar with the limitations of tape measures and multitudes of 2D photographs. In recent years new technologies have emerged to address these limitations, including laser scanners that produce point clouds and 3D photography systems like Matterport and the RICOH THETA X camera and suite of cloud applications. STA has often been an early adopter of these emergent technologies, developing new capabilities that advance the firm’s practice to benefit its clients.

The THETA X camera has become invaluable to us…we have started bringing it to every single job site meeting just as a second tool. We are already talking about getting a second one.

The RICOH THETA X 360-degree camera and its attendant cloud applications are the latest digital tool the firm has test deployed. “The THETA X camera has become invaluable to us,” adds Main, “we have started bringing it to every single job site meeting just as a second tool. We are already talking about getting a second one.”

An image of the RICOH THETA X camera on the desk of an architect. The popular 360-degree cameras work alone, integrate with Matterport and similar solutions, and, importantly, work with RICOH360 Projects and RICOH360 Tours web applications for AEC and real estate. (Image: Ricoh / Kevin Marple. All rights reserved.)

For STA, the challenge of capturing all the critical data in existing buildings has many aspects, including cost, time, and staff. For example, while the firm owns a FARO laser scanner for creating point clouds, Bobby Main notes that the setup time alone isn’t always advantageous to various site meeting circumstances. “The FARO is not an easy thing to just pull out and use,” he adds.

Existing Conditions—STA Processes

The firm’s standard process with any project working within an existing structure or site is to capture accurate dimensional data. They rely on the FARO scanner, which produces point clouds stitched together. The firm also uses Matterport and now has added the RICOH THETA X 360-degree camera that generates spherical imagery up to an 11K image resolution.

While the process may begin with the FARO scanner, it by no means can end there. Those very accurate point clouds get processed and stitched together in Autodesk ReCap software which then exports them into a format Autodesk Revit can ingest. At that point, the point cloud data enables the firm’s architects and designers to create BIM models for their projects in Revit.

While the FARO scanner and its point clouds enable vital steps to an existing conditions BIM model, there are multiple process steps STA requires that it cannot meet.

MORE: Product In-Depth: Ricoh THETA X for the AEC Industry

“We have, of course, used the point clouds to go back in and check things, but the THETA X has been much easier and faster for subsequent data checks,” says Main. Once the firm is beyond the point clouds and the BIM model, they have used the THETA X 360-degree spherical panorama imagery to revisit the existing project site virtually. And it is not just due to speed, as the THETA X imagery is super high-resolution and enables excellent visual review of site conditions beyond what a point cloud can provide.

RICOH THETA X is an affordable, easy-to-use 360-degree spherical high-def camera system ideal for reality capture in the AEC markets. (Image: Kevin Marple / Ricoh)

Another factor for STA using the THETA X for high-resolution spherical imagery is project onboarding. “We are a small office of 11 people, and we do a lot of projects at once,” adds Main. “Sometimes people need to jump around on different projects. We have found it very useful to enter the project and get up-to-speed with the existing conditions and requirements via three-dimensional virtual imagery from photographs.

THETA X and Matterport

“It’s much more cost-effective than taking more trips out to the building site,” adds Main, who notes that bothering the client, a current tenant, or even the building owner with access to the space can sometimes be an encumbrance worth avoiding.

The imagery shot with the THETA X has been dropped into Matterport, a reality capture platform that provides a “dollhouse view” of 3D photogrammetry mapped space. Shown below is STA’s new space for their as-yet unbuilt new office. (Image: STA / All rights reserved)

Matterport’s technology creates 3D immersive digital twins of existing spaces. When trialing the THETA X camera, Bobby Main implemented a Matterport digital twin using 360-degree spherical photography taken by the RICOH THETA X camera. Matterport even showcases and sells the 360-degree camera.

However, while Matterport has provided a solution for STA, RICOH360 Tours offers a similar solution that Main has tested. “I would say that RICOH360 Tours and Matterport are very similar in creating that walk-through experience, so valuable to onboarding staff or leading anybody through the experience of an environment,” says Main. “And frankly, we might use Tours more in the future.”

RICOH360 Tours takes 360-degree spherical photography from THETA cameras and seamlessly stitches together whole building environments. It doesn’t generate a “doll house view” like Matterport, but Main says that feature, while nice to have, isn’t a must-have.

Sample virtual tour of a New York City apartment. Photo by Sam Rohn.

“What will help us better is being able to capture more accurate dimensional data from these photograph 3D tools,” says Main, who reports that Matterport can be wildly inaccurate. Main says that not having to lug a FARO around all the time would be hugely valuable, so he is looking forward to the future when Ricoh will add LiDAR technology to one of its THETA cameras.

THETA X and the Construction Phase

THETA cameras are now playing a more significant role in the construction phase of buildings, especially when paired with RICOH360 Projects.

“Some of the contractors building our projects are using RICOH360 Projects,” says Main. “We can tap into that data, and it has been very helpful because we can see how the project looked each week.” Architosh has written about RICOH360 Projects in some detail in another article; in summary, the cloud-based application enables 360-degree imagery to be uploaded into an application where the user can map those images to floor plan files and then link them all together into a cohesive virtual experience.

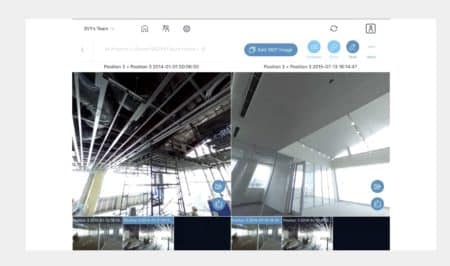

The side-by-side compare feature allows the user to interactively compare two reality capture 360-degree spherical images. As you rotate in one image, the other synchronizes and moves with it.

What differentiates RICOH360 Projects from RICOH360 Tours is the former is a collaboration tool for construction industry professionals that allows team members to pin 360-degree images to floor plans and allow for real-time edits and markups directly on the images. It also allows for time-stamped side-by-side comparisons of these 360-degree images that enrich the collaboration and review process of construction progress monitoring. RICOH360 Tours is designed to convey the layout of the completed property. Some users even use 360 Tours to show photos of their work in progress.

Some of the contractors building our projects are using RICOH360 Projects. We can tap into that data, and it has been very helpful because we can see how the project looked each week.

“It’s beneficial,” adds Main, “because you can ask, ‘oh, was that thing actually installed above the ceiling?’ and go back and look. Having the ability to go through a timeline and sift through that kind of data is invaluable during construction.”

Benefits of THETA X

The THETA X 360-degree spherical camera was purpose-built for the AEC industry professional, and both architects, designers, and contractors are finding it immensely useful, both in conjunction with vastly more expensive 3D laser scanners and in combination with immersive virtual software platforms like Matterport.

The THETA X adds value to STA’s processes, particularly at the earliest project stage of collecting site spatial and current conditions data. And it adds value during construction in tracking progress week by week. Finally, it benefits the firm during all phases where staff must switch to other projects and quickly onboard.

Architects and engineers—and not just general contractors—can benefit from reality capture technology like the RICOH THETA X cameras. They offer a cost-effective means to capture and monitor construction progress and existing conditions, the latter being very important for design and engineering professionals.

THETA X helps AEC users produce 3D immersive as-builts and existing conditions and share and collaborate on those immersive assets with other project stakeholders.

“I think really just having those eyes on the site because the cameras capture things that I may not have noticed when I was on-site offers incredible value,” says Main, speaking of the benefits of THETA X with RICOH360 Projects. “So rather than chasing down the contractor to go double-check something for me or drive back out to the site, I can pull up these 360-degree immersive images and take a look myself.”