EARLIER THIS FALL AUTODESK made a significant strategic investment in closing the feedback loop in the AEC world. That “loop,” as it is commonly referred to in the building industry, is the data feedback loop that goes from design to operations and maintenance and back around again, informing design.

The industry acronym AECOM (not nearly as common as AEC) in some ways sums that up, though the “M” can also stand for management. Architosh had a chance to speak to Nicolas Mangon, VP, AEC Strategy, Autodesk, about its investments in iOFFICE + SpaceIQ, to understand what this all means for Autodesk and its ability to close the loop in AECOM for its customers.

Closing the Loop 20 Years Later

“You know when we started with BIM, it was 20 years ago here in Waltham,” says Mangon reflecting on the company’s history with Revit. “It started with architecture, and then we moved to structural and MEP engineers.” Over the past half-decade, the US-based design software company has then delivered software for construction professionals as it marches through serving all the constituents of the AECOM industry.

What you will see in a complex building like a hospital is that 70 – 80 percent of the total cost of ownership is in the operations phase, over a typical 20-year period.

“Back then, with people like Phil Bernstein, we talked about taking BIM to construction and facilities—this was 20 years ago,” he adds before acknowledging that the BIM transition within the building industry has taken longer than imagined. But Mangon is enthusiastic in our conversation, noting that this latest investment is one of Autodesk’s first and latest moves to address operations, maintenance professionals, and building owners.

Autodesk Tandem is the company’s flagship digital twins platform but connects data across other post-construction tools. The company intends Tandem to be the “digital handover” that correlates to the “physical handover” a contractor delivers to an owner. (Image: Autodesk)

This latest round of investments pairs up with Autodesk Tandem, the company’s “digital twins” platform, and recent acquisitions like Spacemaker and Innovyze. “What you are starting to see is we are more involved in post-construction,” he says. “What you will see in a complex building like a hospital is that 70 – 80 percent of the total cost of ownership is in the operations phase, over a typical 20-year period. So, there is a lot of value that can be created in post-construction.”

Beyond Predicting Failure

The AECOM industry is currently searching for new technological solutions that leverage not just shared data—to eliminate data replication and data silos—but access to the right data. On the operations side of things, owners are finding great value in being able to predict failure in the many building systems in their building assets.

IoT sensors today feed continuous data streams into computer-aided facilities management (CAFM) software. This is one aspect of Innovyze’s water plant infrastructure software where system downtime can be financially punishing for owner-operators. Yet, Mangon says much more can be done than sensor data for operations.

Back then, with people like Phil Bernstein, we talked about taking BIM to construction and facilities—this was 20 years ago…

He makes the note that the vast majority of buildings in operation today, even ones with LEED AP Platinum certifications, we don’t know how things are performing. “Is that thing performing like it was designed?” he asks rhetorically. “I think we don’t know.”

Connecting building systems to IoT sensors and that data to CAFM software is the lower hanging fruit in closing the loop in AECOM in the era of digital twins. The industry can go way beyond predicting failure.

Autodesk wants to drive this data loop around for years across hundreds of thousands of buildings and infrastructure and then utilize AI-based design tools like Spacemaker to help asset owners make intelligent decisions early in the pre-design planning stages for capital expenditure.

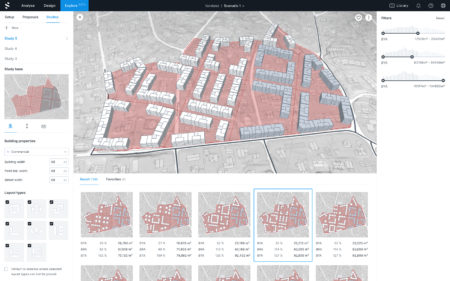

Today Spacemaker largely works with data about its physical context and its climate. In the future, data from actual digital twins will feed into Spacemaker where AI will use it to help generate smarter solutions that combine with AI-generated solutions about a building’s site and climate.

“Today, what Spacemaker does is utilize data about its physical environment and its climate,” he notes. “What we don’t take into account is past experience.” Spacemaker, which Architosh has written about in detail, uses artificial intelligence (AI) to generate design options around design input criteria. (see: Architosh, “INSIDER: The Fourth Revolution—How Spacemaker AI Optimizes Architecture Development,” 26 July 2021)

In the near future, Autodesk might be able to leverage data connections for many hospitals in a particular region and take that data into a tool like Spacemaker. Once inside Spacemaker, that data will be translated into rich information helpful in designing better and more performative hospitals.

Tools for Owners

“Performative buildings” is a broad term. Mangon admits it can mean many things—from how a building functions for social distancing during a global pandemic like the one we are now facing; to how a building encourages creative interaction, like how Steve Jobs imagined the circular Apple campus building by Foster + Partners; to how satisfied Millennial employees are with their workspaces.

“These days, Millennials are thinking about their spaces where they work and if they are good for the environment. All of it goes up on social media,” he says. “So owners want to look at some of the trends in terms of satisfaction and help predict if people are going to renew their leases.” Mangon says this kind of data is the kind of data that SpaceIO and iOFFICE can collect, and it helps building owners know if they should renovate, tear the space down, or buy the next building two blocks away and do the same thing.

iOFFICE + SpaceIQ (merged companies as of this year) offer tools for building owners that span the gamut from “workplace” or employee experience, to facilities management, to real estate management software systems. With over 10,000 customers globally, the two combined companies possess millions of data points that can serve as a starting basis for how Autodesk can strategically align data with their pre-design and digital twins software systems.

“There is already some integration of data today,” says Mangon, “but it is mostly going from design and construction into that space. Most of the time, it is 2D drawings or text data. It brings value, but it only scratches the surface of what can be done.”

Digital Twins

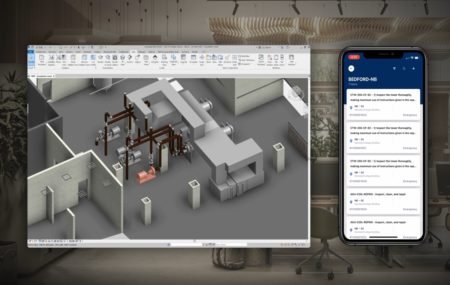

So as we look at how “closing the loop” means taking data from operations and maintenance and generating rich information that can inform decision-making, Mangon says that for Autodesk, the centerpiece technology is digital twins. And their digital twins’ technology platform is Autodesk Tandem.

“Historically, we build tools for architects, designers, and engineers—like AutoCAD and Revit and Civil3D,” he says. “Then we brought to market tools for construction companies. However, Tandem was built for owners. We had never before built a tool for owners from the owner’s perspective.”

They don’t care about clash detection or on-site logistics. So they need a tool for them.

He explains that one key thing owners do is “capital planning,” and Spacemaker is in that area and helps serve that function. He says that owners during the capital planning phase want to interact with the architect and the construction company and get what they need, but they have trouble getting it. “They don’t care about clash detection or on-site logistics. So they need a tool for them.”

“So the goal is—just like a construction company delivers a physical asset—Tandem delivers a digital asset,” says Mangon. He notes that owners don’t embrace BIM more because they never get what they want. Tandem is designed to give them exactly what they want.

With Autodesk Tandem at the center of the digital twin deliverable to owners, Autodesk can now connect other software systems such as Innovyze, Spacemaker, and the solutions from iOFFICE + SpaceIQ, bringing data full circle in the design-build-operate lifecycle.

The End Goal

Nicolas Mangon is ending the conversation by talking about different levels of digital maturity. From the owner’s side of things, the more sophisticated owners of the world, like Microsoft, are 100 percent BIM-centric with operations and maintenance. “That said, a large majority of the world continues to use 2D plan views in operations. So we can streamline this operation of getting data from Revit and AutoCAD into Tandem and tools like SpaceIQ,” he said. “We need to have different steps for different folks as we move customers from 2D to BIM and from BIM to the cloud.” The end goal is closing the feedback loop, and there will be different ways to get there.

Reader Comments

Comments for this story are closed