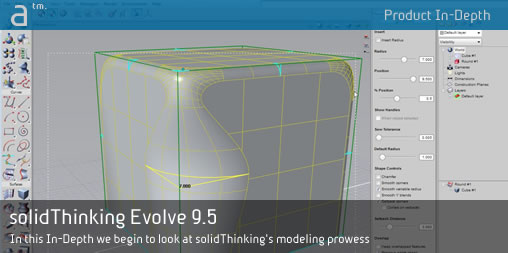

In the early part of the summer we had a chance to sit down over a webcast with the solidThinking folks about their products–what at this point include two: solidThinking Evolve and solidThinking Inspire, both now at version 9.5. The purpose of this first sit-down was to allow us to get much more familiar with how one works directly in solidThinking and in Evolve in particular.

Advertisement

solidThinking, Inc., has extensive far-reaching plans for the evolution of this software–one of the premier product styling or computer-aided industrial design (CAID) programs in the world and one of a few limited products in this league that runs on the Mac. Of course we wanted to talk with them about that. If you recall our AIA Denver reports Altair–solidThinking’s parent company–was at the show primarily showing off technology squarely aimed at the architecture market but utilizing FEA and other engineering technology. But what about solidThinking itself? Well, Altair wasn’t really focused on showing that at the AIA show though they did have it on display as a second cast member. That is not to say they don’t see solidThinking as serving the architecture market–they do. But while it is already utilized it is not the product’s primary focus market. That market is industrial design.

Today’s Most Advanced Architectural Buildings Are Not Unlike Industrial Products

From our view we see the merging of modeling technologies impacting both MCAD and AEC CAD markets as having several common themes and technology thrusts. Firstly there is the direct-modeling (explicit modeling) movement afoot in the MCAD space. Secondly there is the further parametrization and associativity progress being made with BIM. Also, there is the focus with architectural modelers to enable them to not only get more associative but to include features that act a bit like “deformers” that can reshape entire sequences of modeling elements with one quick maneuver.

The subtitle’s implicit argument above is not new. Frank Gehry has been using an aerospace industry CAD product (CATIA) for over a decade and built a second company around it in Gehry Technologies‘ Digital Project. If software for designing jets can be useful and specifically beneficial for Gehry’s architectural creations, might software created for designing industrial products like coffee makers and sailing boats also be useful to creating architecture?

The short answer is “increasingly yes.”

Indeed solidThinking Evolve and Inspire both have fruitful impacts on the AEC space. Yet our thinking lately has been keenly interested in solidThinking’s industry-leading Construction Tree history capabilities and specifically how beneficial such technology could be for iterative work in architecture. Especially at the conceptual and design development stages.

Getting Familiar with solidThinking

Today in this feature we will begin to touch on conceptual architectural modeling in solidThinking a tiny bit. That is not the primary focus for this article. This feature is about getting familiar with Evolve’s modeling prowess in general, which will be a multi-article process as we delve into everything there is to know about solidThinking.

solidThinking’s strength is in the area of surface modeling (curved or organic surfaces) with parametric control and editing and the ability to scale those surfaces. Tony Norton, of solidThinking set me up with his European colleague Adel Matar, who is a solidThinking expert, to show me some of Evolve’s modeling capabilities.

The Chair

Adel starting by drawing just two primary elements. The first was a primary shape which he extruded to form the back of the chair. This was a NURBS curved element. The second element was the trim curve, a spline or NURBS based curve, in 3D space that defines the top edge of the chair in 3D. This second trim element is just as important as the primary initial shape for the chair in the final design because one can keep going back to it and redoing the curve to give the final chair design a new shape. (see images 01 – 02)

01 – The chair consist primarily of two elements, both NURBS curved based and parametrically controlled.

02 – The second curve is used for clipping the top of the chair and giving it its slope and overall definition.

With solidThinking Evolve 9.5 it is quick to get to this level of design with just focusing on two essential elements as discussed above. The primary NURBS curve gained a thickness early in its definition. That thickness is a parameter that can be edited at any time. The curve itself and the vertices that make it up too are also editable by simply select highlighting and altering. The curve can be redrawn a thousand different ways with numerical input finesse if desired. And of course the clipping curve gives the chair its critical design slope.

There are of course other things that need to take place in the design of this club chair. One is the caps or flat ends of sections like the chair top or arm. Those faces get curved quickly with numerical control in the dialog boxes using the Round command. Another key aspect to designing industrial products like furniture is handling the blending of surfaces. solidThinking Evolve does this very well with a large degree of control options.

In our example shown below the two surfaces defining the caps are set to match each other. There are controls that enable the tangent planes to be inverted (both, one or neither), options for following surface isoparms on either surface one or surface two or allow for direct UV editing as well as handling smoothness in absolute or scaling terms and an overall quality setting slider. (see image 03)

Blends are very important but they are not the only thing we are looking at in this chair model. The tops of the chair near the arm section is wider than other parts along that section (the original extruded width). solidThinking Evolve 9.5 allows you to highlight individual vertices one by one or select all of them on a hull (the company’s term for vertices connected in a particular row) by clicking on the hull itself. And then once selected you can manipulate the vertices like for instance scaling up or down. This was the process to giving that edge some additional width.

next page: Visual Qualities and Rendering

Reader Comments

@djnelson75 @architosh Models can be divided with Groups, Layers, or by cataloging parts in the Model Browser.

@Anthony Yes that would be great, or some type of linked block. The problem is, that you get to a point in the design process where you need to know how many bolts you are using, and if you are using the same ones to connect different parts.

@Anthony Yes that would be great, or some type of linked block. The problem is, that you get to a point in the design process where you need to know how many bolts you are using, and if you are using the same ones to connect different parts.

@solidThinking @architosh That is what I like about solidthinking, but at some point you have find out how many bolts you are using.

@solidThinking @architosh That is what I like about solidthinking, but at some point you have find out how many bolts you are using.

@solidThinking @architosh Cataloging parts sounds interesting is that something new? I couldn’t find it in the 8.5 help file(our last trial)

@solidThinking @architosh Cataloging parts sounds interesting is that something new? I couldn’t find it in the 8.5 help file(our last trial)

From http://t.co/7zVtgnx1nw…”Product In-Depth: SolidThinking Evolve 9.5′s Modeling Prowess” http://t.co/zG22jv92Vg

From http://t.co/7zVtgnx1nw…”Product In-Depth: SolidThinking Evolve 9.5′s Modeling Prowess” http://t.co/zG22jv92Vg

@djnelson75,

Well the solidThinking folks are chiming in on this and listening in…perhaps what you seek will come in a future update. 🙂

@djnelson75,

Well the solidThinking folks are chiming in on this and listening in…perhaps what you seek will come in a future update. 🙂

Comments are closed.