Continued from page 1

Moving to Big BIM

Getting to Big BIM took three-plus years. As Illig says, “we had a few projects that started as Big BIM which fell back to Little BIM — there were lots of reasons why this happened.” As he explained, sometimes, the engineers were not mandated by contract to deliver BIM models but agreed to make an attempt. When scheduling pressures mounted or issues developed, consultants fell back on 2D workflows.

Other challenges included internal staff competencies. “We founded the CAD team, and I have four people right now who are spreading skills throughout the office. We have one person placed in every team of about 10-12 people.” His CAD team quickly learned they needed to formalize BIM training in the office.

An apartment building for the client, Bonava Deutschland GmbH, called Schlossstraße Remseck was the firm’s first Big BIM project with complete BIM integration with all stakeholder partners. (Image: ARP Stuttgart / Architosh. All rights reserved.)

“Before coronavirus,” he adds, “we had training for once a week for one hour where we would focus on stairs or windows, for example. We have 15-20 topics on a schedule, and once we get through those, we repeat because things change in Vectorworks.” Part of overcoming the challenges to Big BIM adoption internally was developing ARP’s curriculum with the help of specific training from their local Vectorworks reseller, ComputerWorks GmbH.

Illig has now worked on a few Big BIM projects and is currently planning a high-rise residential project in full BIM. “We are just getting experience as we embark on early Big BIM projects. It is a bit of a learning phase,” he suggests modestly. “At the moment, we are trying out Solibri, and we are on the Macintosh, so that was the only good software solution for us.”

A new high-rise housing project (Apartment building Bürgerhospital Stuttgart) in Germany for the client SWSG Stuttgart. (Image: ARP Stuttgart / Architosh. All rights reserved.)

They have also found the Vectorworks clip cube technology beneficial for investigating issues. Additionally, Illig says that the BIM Collaboration Format (BCF) method of coordinating projects is also helpful. “I think the BCF workflow works fine for me so far,” he adds.

The Sensible Hybrid Tool

Illig says that Vectorworks has enabled their firm to approach BIM workflows in small steps, gaining insight and competencies with each project. Even with full Big BIM projects, the need for 2D doesn’t entirely go away.

“We use Vectorworks in 2D for all the detail work, scales from 1:5 to 1:10, where all the windows, doors, ceiling and roof conditions need detailed drawings,” he says. Certain things are not useful to do in BIM, he contends, citing metal cladding systems at detail-grade where craftsmen can manufacture and construct the product.

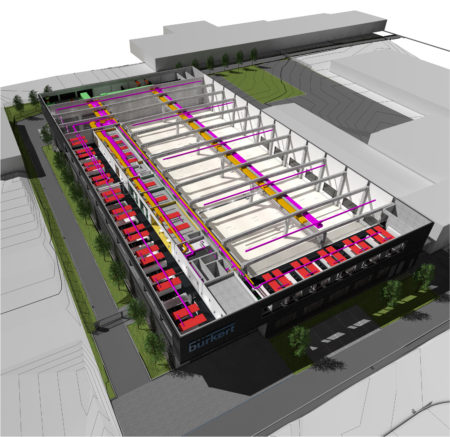

The firm uses Solibri with Vectorworks Architect to conduct clash detection, shown here a project for the client Bürkert GmbH & Co. KG. (Image: ARP Stuttgart / Architosh. All rights reserved.).

“And, we still do early-stage and quick studies in 2D,” he adds. “This is one excellent strength in Vectorworks—in doing quick but high-quality illustration-based work.”

Then there is the German context—an AECO environment where even within the same building or use types, BIM usage, and value perceptions vary. “Some clients don’t see the value of it,” he says of clients and BIM workflows. “The contractors get a big benefit out of it; they get quantities and calculations, which is a huge benefit for them in time saved.”

And, we still do early-stage and quick studies in 2D. This is one excellent strength in Vectorworks—in doing quick but high-quality illustration-based work.

He also suggests that what architects outside of Germany may not understand is the role German architects play in being responsible for quantifications and costs in the project’s planning stages.

“I think there are three major benefits of Big BIM for us here in Germany,” he says. “One is getting all your drawings automatically, the second is the coordination of your design with the engineers and preventing clashes through detection, and third, getting quantifications of your materials for cost purposes.” He contends that it is this third part that can be complex. “It is the job of the architect to tell the client the costs of projects.”

“Competition for a Headoffice“ for an unnamed client in Europe. (Image: ARP Stuttgart / Architosh. All rights reserved.)

For ARP ArchitektenPartnerschaft, Vectorworks’ hybrid nature is perfectly suited to the firm’s German context where BIM adoption itself is fragmented and where pressures on real-life projects require flexibility and scalability in digital workflow transformation, something Vectorworks’ handles well.

Image Credits

Format equates to “party with copyright” / “party with reserved rights of use.” (eg: image: ARP Stuttgart / Architosh. All rights reserved.) Non-credited images are copyrighted to Architosh.

Title Credit: Production-Building in Menden, client: Bürkert GmbH & Co. KG. (Image: ARP Stuttgart / Architosh. All rights reserved.)

Reader Comments

Comments for this story are closed