Continued from page 2

Ultimaker’s 3D Printers and How They Work

When it comes to 3D printers the cost levers behind such machines may surprise you. Basically the bigger the machine the bigger the cost. The speed of 3D printing is not a cost lever, unlike printing on paper. “They all have the same speed,” says Kawola. “In the more expensive 3D printers folks are paying for items like more automation, and cameras to watch the print develop.”

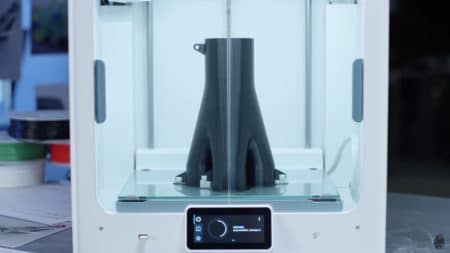

04 – The Ultimaker S5 in action printing a 3D part. The plastic color is based on the type of material and there are many different types of plastics that users can print with, all having various properties like rigidity, strength, temperature-based stability, water-soluble, etc.. (image: Ultimaker / Architosh. All rights reserved.)

Ultimaker makes three models—the Ultimaker 2+, the Ultimaker 3, and the Ultimaker S5. The 2+ is single-extrusion, while the 3 and S5 are double-extrusion. Bigger 3D printers allow you to make slightly larger parts but they involve larger motors which increase cost. Sensors increase in the more expensive model which give you the automation features customers want. Double extrusion printers allow you to print in two colors of plastic, and there are advantages there.

It’s not just how fast the head can move around on the motors, it’s about how fast can the material cool down.

As for speed, Kawola says that “speed is based on thermodynamics based on the materials and the choreography of how the head moves around the part.” In other words, plastic must form solid before another strip can be laid on top or next to it. “It’s not just how fast the head can move around on the motors, it’s about how fast can the material cool down,” adds Kawola.

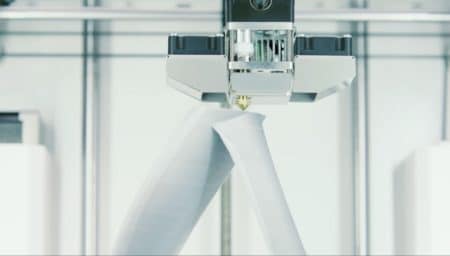

The temperature difference of the plastic used in 3D printing between the liquid state and solid state is about 10 degrees. “We want to be just on the edge of that line,” says Kawola, “there is zero reason to be more fluid or more liquid, it is just like a glue gun—same principle.” To get the accuracy of crisp corners it all depends on the bead size. The bead sizes vary. Kawola says the standard is 0.4mm but users have nozzle size options with Ultimaker printers and there is also 0.25mm, 0.6mm, and 0.8mm options. Nozzle size is inverse to speed. “The smaller the nozzle size the slower the speed of the printer,” he adds.

05 – Users have options to buy different nozzles with different thickness in terms of bead size, from 0.25mm to 0.4mm, to 0.6mm to 0.8mm. Sprint speed is inverse to nozzle size so the smaller the nozzle the slower the overall print job. (image: Ultimaker / Architosh. All rights reserved.)

You can get more accuracy with the smaller nozzles but it comes at the price of speed. Models can take 10 hours to print. But this is where the 3D printing industry takes an interesting turn. “The speed hasn’t been a deterrent to 3D printing,” he says, “because at a $3,000 price point companies just get another printer.” Still, there is research going on to develop different materials with better thermodynamics. One such company is Markforged, another Metro Boston company. Markforged has developed 3D printing materials like HSHT Fiberglass and Kevlar, for example. The range of use and opportunity in 3D printer materials is vast.

The Dows and Owens Corning’s are now in the market on the material side. Kawola says these guys can maybe drive down the costs which will impact the use of 3D printing for actual production runs. Today the costs of materials are still too prohibitive. Plastic resin is $4 a pound, an order of magnitude too expensive for actual production runs of mass manufactured plastic items. But things will only get better with innovation and competition in the market and Ultimaker is innovating and serving a growing 3D printer market.

06 – A view of a print nozzle in the Ultimaker 3D printer. (image: Ultimaker / Architosh. All rights reserved.)

For its part, Ultimaker has three fantastic 3D printers. The Ultimaker 2+ starts at just $2,499 and is the entry-level model. It doesn’t feature a camera but it has swappable nozzle support for 0.25, 0.4, 0.6 and 0.8mm print beads for greater accuracy or faster print speed. The Ultimaker 2 Extended+ is the same machine but in a taller volume for bigger parts.

The Ultimaker 3 features dual extrusion. It can, therefore, print in two colors, one color each nozzle. It also features a camera and WiFi, Ethernet and USB connectivity so users can print directly to the printer. The mid-level machine costs $3,495 and also comes in an extended taller volume model.

The flagship model is the Ultimaker S5, which costs $5,995. It is the largest of the three models and helps companies print bigger parts. It uniquely features a color touch control panel for operation. Otherwise, the S5 and 3 are similar dual-extrusion machines with similar connectivity and other features. And speaking of extrusions, all three models have the capacity for multiple material support. Materials vary from Nylon, PLA, ABS, CPE, PVA, PC, TPU 95A and others.

3D Printers and Architects—Ultimaker’s Six Reasons

Ultimaker may only sell 5 percent of their 3D printers to architecture firms but that doesn’t mean anything in the true take-up of 3D printers. Manufacturing and education are the two biggest markets for 3D printing in general, in that order, but there is continuing traction in AEC fields. For architects many times they are making physical models at far lower costs and with faster outcomes.

07 – Make Ltd, Architects out of the UK, Hong Kong and Sydney are big believers in Ultimaker’s 3D printers for modeling making. (image: Ultimaker / Architosh. All rights reserved.)

The Dutch company has an excellent customer profile story on Make Ltd, an architecture firm founded by Ken Shuttleworth in 2004. The London-based firm has offices in Hong Kong and Sydney and over 150 employees. The firm, which prior to their selection of Ultimaker 3D printers, used traditional hand-cut models from foam and cardboard. While this page details their use of 3D printers there is a very good video that provides a good view of how they are using these printers for modeling making and for iterative design work in their firm.

Architects can also use 3D printers for making custom-designed parts for buildings at scale. Custom door hardware, stair parts like handrails and balusters and some of the things that architects are using 3D printers for, as well as specialized parts with complex textures. As seen here, it is possible to design sophisticated lattice-like patterns and structures and sometimes only 3D printers can create these. What you can do is really quite endless and open to one’s imagination.

Image Credits

Format equates to “party with copyright” / “party with reserved rights of use.” (eg: image: FJMT / Architosh. All rights reserved.)

Title image credit: ( Ultimaker / Architosh. All rights reserved.) Not credited images are copyrighted to Architosh. All other images are copyrighted, as noted in the image credits.

Reader Comments

Comments for this story are closed