THERE IS OFTEN A MISCONCEPTION that speed and design are at fundamental odds with each other—that the latter will always compromise the former. But why is that?

The Meaning of Speed

One key reason is that good design requires the ingredient of time itself. For Stamhuis, they are learning how to gain back more time so their designers can take on more strategic work, by tapping the power of generative design through Dynamo. What the Netherlands-based company saves on time, they also give back to the project client.

Stamhuis’s specialty is the design and build-out of liquor stores, convenience stores, and supermarkets. In this market, time is of the essence for their clients; when stores go through remodels, customers will temporarily shop elsewhere. It is critical that store renovations are back up and running before customers adopt substitutes permanently. So time—far from being the enemy of good design—in this case, is a vital ingredient in client success.

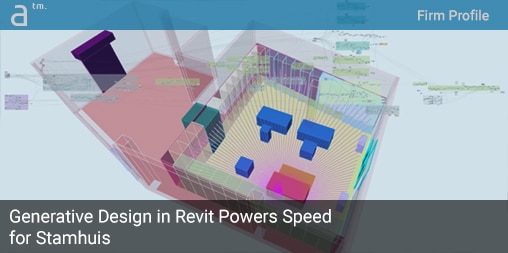

The master Dynamo script establishes a sophisticated semi-automated design workflow within Autodesk Revit offering Stamhuis a massive speed-up in laying out retail stores for its many clients. The system utilizes the company’s very large Revit family objects. (Image: Stamhuis / Architosh. All rights reserved.)

Speed, in the case of Stamhuis’s accomplishments, is virtuous on two fronts. Faster project delivery helps clients with success, faster processes due to Dynamo utilization help Stamhuis designers take on more strategic work, ultimately benefitting the company and its clients.

So how did they get there?

Applied Modularity and Interchangeability

Ron Rijkers, Team Manager for BIM and Innovation at Stamhuis, began telling me his company’s story by explaining how they went from CAD to BIM with Revit and from Revit to new emerging technologies like VR and Autodesk generative design tools.

“In retail construction, we start with a 3D laser scan, and we model from that scan,” says Rijkers, who explains his company’s complete delivery process from design to fabrication. Stamhuis will then take the 3D scan of an emptied location and begin the design process. “Everything within these walls will be prefabricated,” he adds. “We have a very large Revit family of elements for our work.”

We just pulled all the decision-making processes and tasks the designer had to do in CAD and put them into the right order, like a schedule, and we started programming.

Stamhuis both designs and provides components for their client stores. Therefore, they have invested in a high degree of modularity and interchangeability of elements, like store shelving systems, counters, check-out lanes, signage, storage, et cetera. “Our buyers are prefabrication specialists, inventory specialists, so we invest a lot of time making all the elements smart and plug-and-play,” says Rijkers.

Working rapidly with interchangeable modular components certainly saves time in Revit during store planning. However, Rijkers and his team began thinking about how to automate the store planning process. The next step was to look at Dynamo.

Automating Design with Dynamo

Stamhuis decided to invest in programming in Dynamo, all the processes, and decisions a designer had to make in BIM. “We just said we should lock ourselves inside a meeting room for a few days,” he adds. “And what Dieter and others from Autodesk saw is that we have standardized libraries, elements, and design inputs—all of which works very well for generative design.”

An overlay image showing a typical design product of Stamhuis’ custom Dynamo scripted automation process with Autodesk BIM solutions. (Image: Stamhuis / Architosh. All rights reserved.)

Making a shift like this takes commitment. Rijkers and his team—which included a liquor store designer and their Dynamo specialist—met with their local Autodesk reseller and their Dynamo expert. “We just pulled all the decision-making processes and tasks the designer had to do in CAD and put them into the right order, like a schedule, and we started programming,” says Rijkers. “In three days, we had a working demo for one project, just by scripting all the tasks the designers do,” he adds.

Stamhuis had already utilized Dynamo in a limited way with Revit, building a functional tool to handle quoting of materials by combining Excel with Dynamo. But this new computational design model with Dynamo and utilizing Autodesk’s Project Refinery (beta) meant Rijker’s team could reduce hour-long tasks down to minutes.

“My new focus is to reduce our modeling time by fifty percent,” says Rijkers. He notes that 70 percent of their engineering work consists of modeling, while 30 percent consists of communication, test control, and information management. While Dynamo could eventually create almost all 3D information, he believes that 20 percent of modeling will still be done manually by their designers.

Streamlining and the Future

Ron Rijkers and his team have been evaluating past store designs by analyzing them with Autodesk Project Refinery and comparing outcomes across various measures. Refinery enables AEC designers of all levels to engage with and optimize their Dynamo designs. It provides a user-interface for the non-scripter/non-programmer.

03 – Stamhuis has now taken their process to include Autodesk’s Project Refinery, enabling non-scripting professionals to explore design options and analyze designs across specific criteria. (Image: Stamhuis) All rights reserved.

Additional optimizations for Stamhuis’s workflows go beyond generative design. The company fabricates components in their shops and uses Autodesk Inventor with their CNC machines. Their concept designers utilize SketchUp so elements inside their stores may start with SketchUp models but eventually need to be Inventor models, while also becoming Revit family objects. A more streamlined process between these three tools is something Rijkers imagines can exist.

Autodesk Backbone

On the management side, while Revit and Dynamo form the center of the BIM processes for design and documentation, the company uses the Autodesk Construction Cloud (BIM 360) platform for project-based information. SharePoint and Office 360 cover all things that they don’t create in BIM 360 but place in BIM 360, while Microsoft Business Central handles company enterprise resource planning (ERP).

With such a well-honed collection of digital technologies, Stamhuis is well poised to deliver excellence in designing and building projects for its clients. By maximizing the integrations of different disciplines—something they did as part of their Open Next Week concept—they can continue to reduce costs and time for their clients.

04 – Another image of Autodesk’s Project Refinery, enabling non-scripting professionals to explore design options and analyze designs across specific criteria. This image is similar to images Architosh published several years ago about Autodesk’s secretive Project Fractal. Refinery is based on that earlier technology. (Image Stamhuis) All rights reserved.

We don’t need to convince them, because every year we try to build better, faster, and cheaper,” says Rijkers. “And when we innovate our supply chain, we can lower our prices—sharing the benefits of innovation while increasing profits for ourselves.”

Image Credits

Format equates to “party with copyright” / “party with reserved rights of use.” (eg: image: Itten+Brechbühl / Architosh. All rights reserved.) Not credited images are copyrighted to Architosh.

Title Credit: ( Image: Stamhuis / Architosh. All rights reserved.)